- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

SHENGTENG

| Product Name | Grain Oriented Silicon Steel | |||

| Standard | B23G110, B27G120, B35G155, B23R080-B27R095 | |||

| Thickness | 0.23mm-0.35mm | |||

| Width | 20mm-1250mm | |||

| Length | Coil Or As Required | |||

| Technique | Cold Rolled | |||

| Surface Treatment | Coated | |||

| Application | Widely used in transformers, generators, various household motors and micro-motors, etc. | |||

| Special Use | Silicon Steel | |||

| Sample | For Free (Within 10 KG) | |||

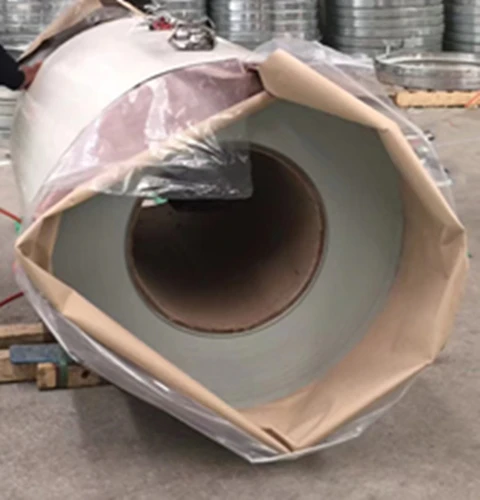

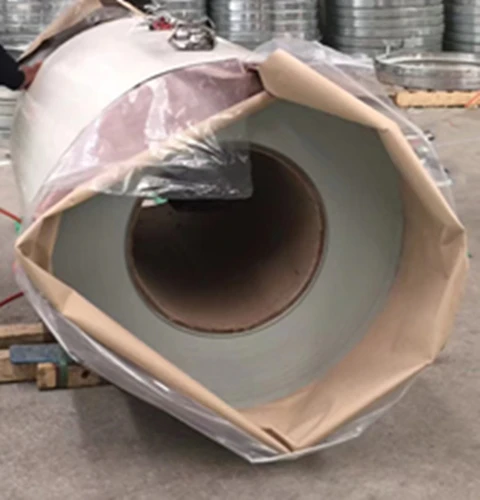

Products Show

The difference between oriented silicon steel and non-oriented silicon steel

Non-oriented silicon steel: ferrosilicon alloy with very low carbon content. In the deformed and annealed steel sheet, its grains are distributed randomly. The silicon content of the alloy is 1.5% to 3.0%, or the sum of the silicon and aluminum content is 1.8% to 4.0%. The products are usually cold-rolled plates or strips, which are mainly used to manufacture motors and generators.

Oriented silicon steel: It has strong directionality, the lowest iron loss value in the rolling direction, the highest magnetic permeability, and a higher magnetic induction value under a certain magnetization field. The silicon content of oriented silicon steel is about 3%. It also requires a low content of oxide inclusions in the steel and must contain certain inhibitors (MnS, A1N).

Products Details

Excellent processing performance:

Excellent processing performance:

Excellent performance of Insulating coating:

ADVANCED TECHNOLOGYThe surface hardness is high,

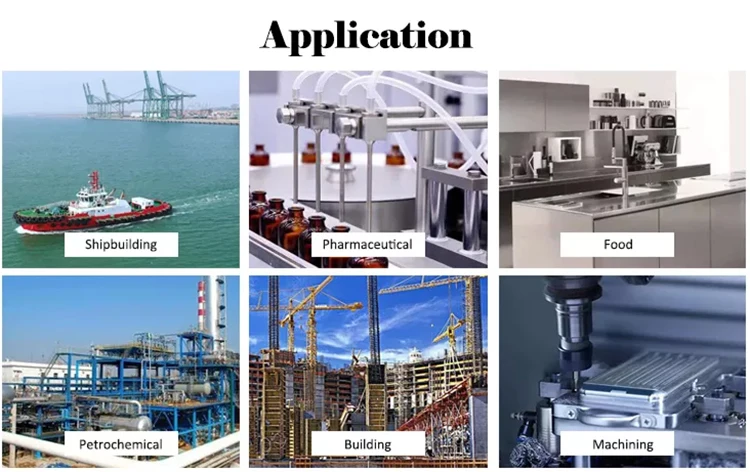

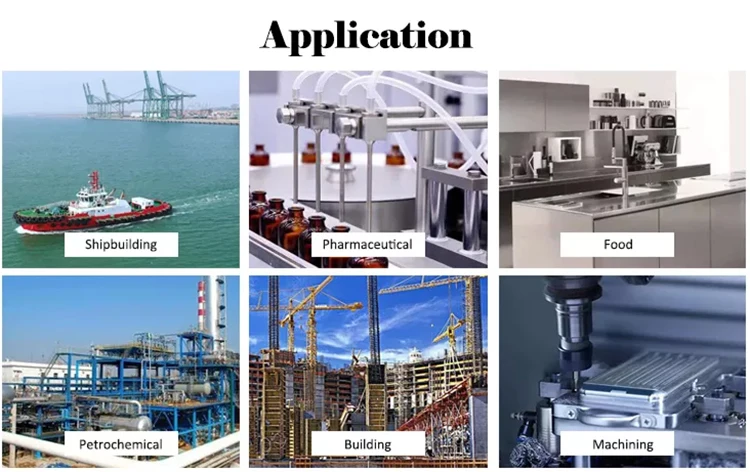

Application

4.Mechanical manufacturing, Pavement slab, ect.

Packing and Delivery

FAQ

1.Q: Why choose us?

| Product Name | Grain Oriented Silicon Steel | |||

| Standard | B23G110, B27G120, B35G155, B23R080-B27R095 | |||

| Thickness | 0.23mm-0.35mm | |||

| Width | 20mm-1250mm | |||

| Length | Coil Or As Required | |||

| Technique | Cold Rolled | |||

| Surface Treatment | Coated | |||

| Application | Widely used in transformers, generators, various household motors and micro-motors, etc. | |||

| Special Use | Silicon Steel | |||

| Sample | For Free (Within 10 KG) | |||

Products Show

The difference between oriented silicon steel and non-oriented silicon steel

Non-oriented silicon steel: ferrosilicon alloy with very low carbon content. In the deformed and annealed steel sheet, its grains are distributed randomly. The silicon content of the alloy is 1.5% to 3.0%, or the sum of the silicon and aluminum content is 1.8% to 4.0%. The products are usually cold-rolled plates or strips, which are mainly used to manufacture motors and generators.

Oriented silicon steel: It has strong directionality, the lowest iron loss value in the rolling direction, the highest magnetic permeability, and a higher magnetic induction value under a certain magnetization field. The silicon content of oriented silicon steel is about 3%. It also requires a low content of oxide inclusions in the steel and must contain certain inhibitors (MnS, A1N).

Products Details

Excellent processing performance:

Excellent processing performance:

Excellent performance of Insulating coating:

ADVANCED TECHNOLOGYThe surface hardness is high,

Application

4.Mechanical manufacturing, Pavement slab, ect.

Packing and Delivery

FAQ

1.Q: Why choose us?