- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

SHENGTENG

Products Description

Aluminium tube is a kind of non-ferrous metal tube, which refers to a metal tubular material that is made of pure aluminum or aluminum alloy by extrusion processing to be hollow along its longitudinal length.There can be one or more closed through holes,with uniform wall thickness and cross section, and delivered in a straight line or in a roll. It is widely used in industries such as automobiles, ships, aerospace, aviation, electrical appliances, agriculture, electromechanical and household appliances.

Aluminum tubes are mainly divided into the following types

According to thickness: ordinary aluminum tube and thin-walled aluminum tube

Product Paramenters

| Model | Aluminum (Aluminium) Tube/Pipe | |||

| Material Grade | 1000 series: 1050,1060,1070,1080,1100,1435, etc 2000 series: 2011,2014,2017,2024, etc 3000 series: 3002,3003,3104,3204,3030, etc 5000 series: 5005,5025,5040,5056,5083, etc 6000 series: 6101,6003,6061,6063,6020,6201,6262,6082, etc 7000 series: 7003,7005,7050,7075, etc | |||

| Size | Outer Diameter:3-250mm | |||

| Wall Thickness: 0.3-50mm | ||||

| Length: 10mm -6000mm | ||||

| Standards | ASTM, ASME,EN, JIS, DIN,GB/T etc | |||

| Surface treatment | Mill finished,anodized,powder coating,Sand blast,etc | |||

| Surface colors | Nature, silver, bronze, champagne, black, gloden, etc As customized | |||

| Status | T4 T5 T6 or other special status | |||

| Usage | aluminum profile for windows/ doors/ decoration/ construction/ curtain wall | |||

| Quality | China Nation Standard GB/T | |||

| Packing | Protective film +plastic film or EPE +kraft paper | |||

| Certificate | ISO 9001 2008 | |||

| MOQ | 1 tons. Usuall 12 tons for a 20 feet contaner; 24 tons for a 40 feet container. | |||

| Press Machine | 500-4000 tons all together 64 press lines | |||

| Moulding | 1. Using our moulds, no fee; 2. Using customer drawing, opening mould, usually about 5 tons the moulding fee is free; 3. Can be diguessed. | |||

Product Applications

Aluminum Tube Tent Aluminum Water Pipe System Aluminum Pipe Railing

Special Aluminum Pipe Aluminum Tube Radiator Shaped Aluminum Pipeline

Product packaging

Normal Package Wooden Case Package Carton Box Package

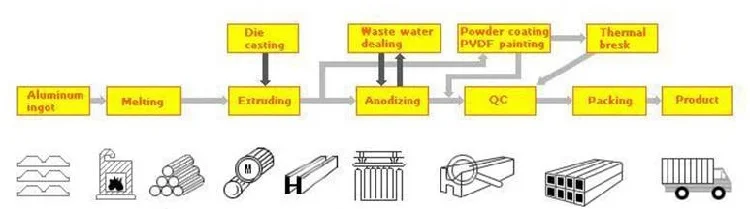

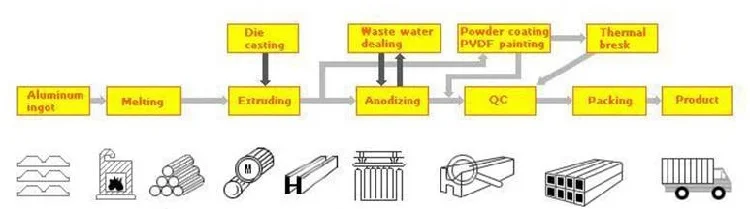

Manufacturing Technique

The alloy aluminum tube profile is mainly produced by the extrusion method, while the wire rod is produced by the stretching method. The most commonly used extrusion processes are forward extrusion and reverse extrusion. Extruded alloy aluminum pipes and profiles adopt the production process of ingot heating-extrusion-finishing; for heat-treated aluminum alloys that can be strengthened, quenching and aging treatment are also required. The aluminum alloy wire adopts the production process of hot extrusion-annealing-stretching-heat treatment-finishing. The aluminum wire for the conductor is mainly produced in the wire factory, and generally adopts the production process of first continuous casting and rolling to produce aluminum wire rod and then stretching.

FAQ

Q. Are you a factory or trading company?

A. We are a factory company.

Q. How to ensure the quality of your products?

A. IS09000, client requirements, product standards, strict inspection to control raw material,production process and final

products

Q. How do you resolve the problem about your products?

A. Person of aging services: For customer complaints commissioner set up a special complaint handling,complaint issues

recorded the first time and find the relevant person in charge of the feedback and resolve. Details check our "Quality

corrective action report"

Q. What is the MOQ?

A. Sample order is acceptable, And some samples can be free.

Q. How long do you need the delivery time?

1)Supply within 5-10 days (product in our Stock list)

2)Custom products need to be calculated according to the quantity

Q.What 's your payment terms?

A. T/T,L/C at sight , Western Union

Q.How can we get your price ?

A. We need below information to quote for you:

1. Product Name

2. Standard

3. Material Grade (Chemical Composition)

4. Dimension

5. Quantity

6. The Drawing for Special Parts

Products Description

Aluminium tube is a kind of non-ferrous metal tube, which refers to a metal tubular material that is made of pure aluminum or aluminum alloy by extrusion processing to be hollow along its longitudinal length.There can be one or more closed through holes,with uniform wall thickness and cross section, and delivered in a straight line or in a roll. It is widely used in industries such as automobiles, ships, aerospace, aviation, electrical appliances, agriculture, electromechanical and household appliances.

Aluminum tubes are mainly divided into the following types

According to thickness: ordinary aluminum tube and thin-walled aluminum tube

Product Paramenters

| Model | Aluminum (Aluminium) Tube/Pipe | |||

| Material Grade | 1000 series: 1050,1060,1070,1080,1100,1435, etc 2000 series: 2011,2014,2017,2024, etc 3000 series: 3002,3003,3104,3204,3030, etc 5000 series: 5005,5025,5040,5056,5083, etc 6000 series: 6101,6003,6061,6063,6020,6201,6262,6082, etc 7000 series: 7003,7005,7050,7075, etc | |||

| Size | Outer Diameter:3-250mm | |||

| Wall Thickness: 0.3-50mm | ||||

| Length: 10mm -6000mm | ||||

| Standards | ASTM, ASME,EN, JIS, DIN,GB/T etc | |||

| Surface treatment | Mill finished,anodized,powder coating,Sand blast,etc | |||

| Surface colors | Nature, silver, bronze, champagne, black, gloden, etc As customized | |||

| Status | T4 T5 T6 or other special status | |||

| Usage | aluminum profile for windows/ doors/ decoration/ construction/ curtain wall | |||

| Quality | China Nation Standard GB/T | |||

| Packing | Protective film +plastic film or EPE +kraft paper | |||

| Certificate | ISO 9001 2008 | |||

| MOQ | 1 tons. Usuall 12 tons for a 20 feet contaner; 24 tons for a 40 feet container. | |||

| Press Machine | 500-4000 tons all together 64 press lines | |||

| Moulding | 1. Using our moulds, no fee; 2. Using customer drawing, opening mould, usually about 5 tons the moulding fee is free; 3. Can be diguessed. | |||

Product Applications

Aluminum Tube Tent Aluminum Water Pipe System Aluminum Pipe Railing

Special Aluminum Pipe Aluminum Tube Radiator Shaped Aluminum Pipeline

Product packaging

Normal Package Wooden Case Package Carton Box Package

Manufacturing Technique

The alloy aluminum tube profile is mainly produced by the extrusion method, while the wire rod is produced by the stretching method. The most commonly used extrusion processes are forward extrusion and reverse extrusion. Extruded alloy aluminum pipes and profiles adopt the production process of ingot heating-extrusion-finishing; for heat-treated aluminum alloys that can be strengthened, quenching and aging treatment are also required. The aluminum alloy wire adopts the production process of hot extrusion-annealing-stretching-heat treatment-finishing. The aluminum wire for the conductor is mainly produced in the wire factory, and generally adopts the production process of first continuous casting and rolling to produce aluminum wire rod and then stretching.

FAQ

Q. Are you a factory or trading company?

A. We are a factory company.

Q. How to ensure the quality of your products?

A. IS09000, client requirements, product standards, strict inspection to control raw material,production process and final

products

Q. How do you resolve the problem about your products?

A. Person of aging services: For customer complaints commissioner set up a special complaint handling,complaint issues

recorded the first time and find the relevant person in charge of the feedback and resolve. Details check our "Quality

corrective action report"

Q. What is the MOQ?

A. Sample order is acceptable, And some samples can be free.

Q. How long do you need the delivery time?

1)Supply within 5-10 days (product in our Stock list)

2)Custom products need to be calculated according to the quantity

Q.What 's your payment terms?

A. T/T,L/C at sight , Western Union

Q.How can we get your price ?

A. We need below information to quote for you:

1. Product Name

2. Standard

3. Material Grade (Chemical Composition)

4. Dimension

5. Quantity

6. The Drawing for Special Parts