- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| PDF Export | |

Basic Info.

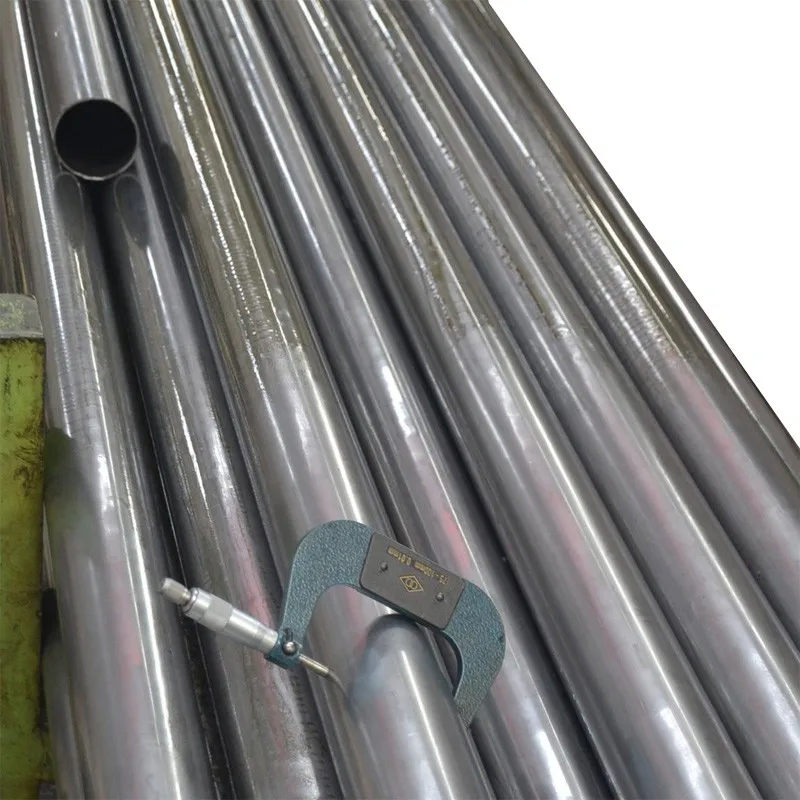

A seamless pipe is a type of steel pipe with a hollow cross - section and no seams along its length. It is typically produced from a solid billet or ingot through processes like piercing, rolling, and drawing.

Seamless pipes have several important functions. Firstly, they are widely used for transporting fluids such as water, oil, and gas. Their seamless structure ensures a smooth flow and high - pressure resistance. Secondly, in mechanical engineering, they are used to make various parts like shafts and cylinders. They can also be used in construction for structural support. Seamless pipes are known for their high strength, durability, and ability to withstand harsh environments, which makes them suitable for a wide range of applications in industries such as energy, manufacturing, and infrastructure.

Product Advantage

No Welding Defects

Seamless pipes are free from welding joints. Welding joints are usually the vulnerable parts of pipes and are likely to have problems like cracks and pores. However, seamless pipes don't have such issues, thus enhancing their reliability and safety. They are extensively applied in industries like oil - gas transmission and aerospace where high safety is demanded.

High Strength

Composed of a single and uniformly - structured metal, seamless pipes possess high strength. They are capable of withstanding significant pressure and tensile forces. In high - pressure oil pipelines or mechanical parts under great stress, seamless pipes can function excellently. For instance, they can endure the great pressure in deep - sea oil drilling.

Corrosion Resistance

Seamless pipes can be manufactured with various materials such as carbon steel, alloy steel and stainless steel based on specific needs. This endows them with corrosion - resistant properties, enabling them to resist the corrosion of acids, alkalis, salts and the atmosphere. In the chemical industry, they are used to convey different corrosive chemical substances and have a long service life.

High Dimensional Precision

The production process of seamless pipes can guarantee high - dimensional accuracy, which can satisfy the precise application requirements in different industries. In precision machinery manufacturing, aerospace and other fields where strict dimensional accuracy is required, seamless pipes can be precisely matched with various devices and structures to ensure the normal operation and overall performance of the equipment.

Products detalis

Products detalis

| thickness | 1.2-30mm or as required | |||

| length | 3-12m or as required | |||

| material | Q195—Grade B, SS330, SPC, S185 Q215—Grade C,CS Type B, SS330, SPHC Q235---Grade D, SS400, S235JR, S235JO, S235J2 Q345---SS500, ST52 etc | |||

| Standard | DIN/ASTM/AISI/GB/JIS/EN etc | |||

| application | Widely used in Structure, Accessorize,Construction, Fluid transportation,machinery parts,the stress parts of the automobile tractor parts and so on | |||

| Package | 1) Big OD: in bulk 2) Small OD: packed by steel strips 3) Plastic bags 4) According to customer’s requirement | |||

| Delivery | 7-15 days according to quantity | |||

| Grade A | |||||||||

| C | Mn | P | S | Si | Cr | Cu | Mo | Ni | V |

| 0.25 | 0.27-0.93 | 0.035 | 0.035 | 0.1 | 0.4 | 0.4 | 0.15 | 0.4 | 0.08 |

| Grade B | |||||||||

| C | Mn | P | S | Si | Cr | Cu | Mo | Ni | V |

| 0.3 | 0.29-1.06 | 0.035 | 0.035 | 0.1 | 0.4 | 0.4 | 0.15 | 0.4 | 0.08 |

| Grade C | |||||||||

| C | Mn | P | S | Si | Cr | Cu | Mo | Ni | V |

| 0.35 | 0.29-1.06 | 0.035 | 0.035 | 0.1 | 0.4 | 0.4 | 0.15 | 0.4 | 0.08 |

Packing and shipping

Packing and shipping

Production Process

①The main production process of hot-rolled seamless steel pipe (△main inspection process): Tube blank preparation and

inspection△→tube blank heating→piercing→tube rolling→steel reheating→fixed (reduced) diameter→heat treatment△→finished pipe

straightening→finishing→inspection△ (non-destructive, physical and chemical, Taiwan inspection)→warehousing ②The main production

process of cold-rolled (drawn) seamless steel pipe: Billet preparation→pickling lubrication→cold rolling (drawing)→heat

treatment→straightening→finishing→inspections.

FAQ

Q1. Are you trading company or manufacturer ?

A: We are professional manufacturer, providing a wide range of steel products.

Q2. Do you provide samples ?

A: Yes ,we would provide samples For Free . The courier freight will be covered by customer’s account.

Q3.what about the payment terms ?

A: We accept different payment terms like T/T, L/C , Cash, Western Union, Alibaba online paying etc .

Q4.How about the delivery time?

A: Normally it takes 15-35 days since order confirmation.

Q5. Could you customized as our request?

A: Yes, just tell your demands, we can offer the customized solution for you, such as material, hardness, thickness,width and so on.

Q6.How can I visit your factory ?

A: Welcome to visit our factory at any time. We will help you accessing the business visa to China . Assist arranging your schedule in China ,including the factory visiting , products quality checking , car picking up, hotel booking , food service etc.

Basic Info.

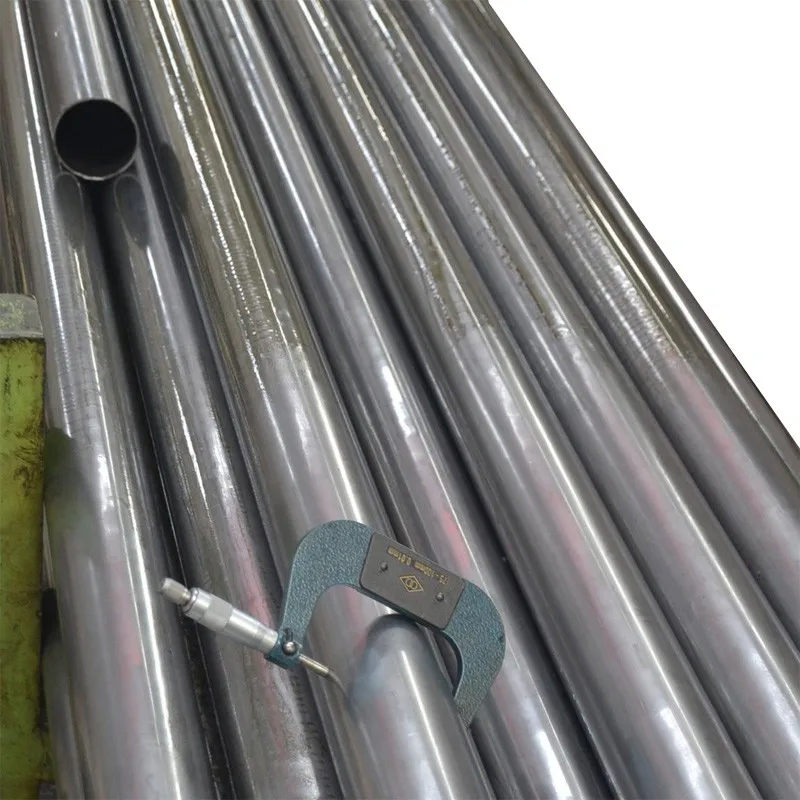

A seamless pipe is a type of steel pipe with a hollow cross - section and no seams along its length. It is typically produced from a solid billet or ingot through processes like piercing, rolling, and drawing.

Seamless pipes have several important functions. Firstly, they are widely used for transporting fluids such as water, oil, and gas. Their seamless structure ensures a smooth flow and high - pressure resistance. Secondly, in mechanical engineering, they are used to make various parts like shafts and cylinders. They can also be used in construction for structural support. Seamless pipes are known for their high strength, durability, and ability to withstand harsh environments, which makes them suitable for a wide range of applications in industries such as energy, manufacturing, and infrastructure.

Product Advantage

No Welding Defects

Seamless pipes are free from welding joints. Welding joints are usually the vulnerable parts of pipes and are likely to have problems like cracks and pores. However, seamless pipes don't have such issues, thus enhancing their reliability and safety. They are extensively applied in industries like oil - gas transmission and aerospace where high safety is demanded.

High Strength

Composed of a single and uniformly - structured metal, seamless pipes possess high strength. They are capable of withstanding significant pressure and tensile forces. In high - pressure oil pipelines or mechanical parts under great stress, seamless pipes can function excellently. For instance, they can endure the great pressure in deep - sea oil drilling.

Corrosion Resistance

Seamless pipes can be manufactured with various materials such as carbon steel, alloy steel and stainless steel based on specific needs. This endows them with corrosion - resistant properties, enabling them to resist the corrosion of acids, alkalis, salts and the atmosphere. In the chemical industry, they are used to convey different corrosive chemical substances and have a long service life.

High Dimensional Precision

The production process of seamless pipes can guarantee high - dimensional accuracy, which can satisfy the precise application requirements in different industries. In precision machinery manufacturing, aerospace and other fields where strict dimensional accuracy is required, seamless pipes can be precisely matched with various devices and structures to ensure the normal operation and overall performance of the equipment.

Products detalis

Products detalis

| thickness | 1.2-30mm or as required | |||

| length | 3-12m or as required | |||

| material | Q195—Grade B, SS330, SPC, S185 Q215—Grade C,CS Type B, SS330, SPHC Q235---Grade D, SS400, S235JR, S235JO, S235J2 Q345---SS500, ST52 etc | |||

| Standard | DIN/ASTM/AISI/GB/JIS/EN etc | |||

| application | Widely used in Structure, Accessorize,Construction, Fluid transportation,machinery parts,the stress parts of the automobile tractor parts and so on | |||

| Package | 1) Big OD: in bulk 2) Small OD: packed by steel strips 3) Plastic bags 4) According to customer’s requirement | |||

| Delivery | 7-15 days according to quantity | |||

| Grade A | |||||||||

| C | Mn | P | S | Si | Cr | Cu | Mo | Ni | V |

| 0.25 | 0.27-0.93 | 0.035 | 0.035 | 0.1 | 0.4 | 0.4 | 0.15 | 0.4 | 0.08 |

| Grade B | |||||||||

| C | Mn | P | S | Si | Cr | Cu | Mo | Ni | V |

| 0.3 | 0.29-1.06 | 0.035 | 0.035 | 0.1 | 0.4 | 0.4 | 0.15 | 0.4 | 0.08 |

| Grade C | |||||||||

| C | Mn | P | S | Si | Cr | Cu | Mo | Ni | V |

| 0.35 | 0.29-1.06 | 0.035 | 0.035 | 0.1 | 0.4 | 0.4 | 0.15 | 0.4 | 0.08 |

Packing and shipping

Packing and shipping

Production Process

①The main production process of hot-rolled seamless steel pipe (△main inspection process): Tube blank preparation and

inspection△→tube blank heating→piercing→tube rolling→steel reheating→fixed (reduced) diameter→heat treatment△→finished pipe

straightening→finishing→inspection△ (non-destructive, physical and chemical, Taiwan inspection)→warehousing ②The main production

process of cold-rolled (drawn) seamless steel pipe: Billet preparation→pickling lubrication→cold rolling (drawing)→heat

treatment→straightening→finishing→inspections.

FAQ

Q1. Are you trading company or manufacturer ?

A: We are professional manufacturer, providing a wide range of steel products.

Q2. Do you provide samples ?

A: Yes ,we would provide samples For Free . The courier freight will be covered by customer’s account.

Q3.what about the payment terms ?

A: We accept different payment terms like T/T, L/C , Cash, Western Union, Alibaba online paying etc .

Q4.How about the delivery time?

A: Normally it takes 15-35 days since order confirmation.

Q5. Could you customized as our request?

A: Yes, just tell your demands, we can offer the customized solution for you, such as material, hardness, thickness,width and so on.

Q6.How can I visit your factory ?

A: Welcome to visit our factory at any time. We will help you accessing the business visa to China . Assist arranging your schedule in China ,including the factory visiting , products quality checking , car picking up, hotel booking , food service etc.