- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

SHENGTENG

Specification

| Grade | 304 stainless steel sheet plate | |

| Surface | 2B, NO.1, BA, NO.4, 8K, HL, Polished, Mill, Embossing, Satin, ect with PVC/PE/Laser film | |

| Executive Standard | Chinese | GB/T14975-2002, GB/T14976-2002, GB/T13296-91 |

| American | ASTM A312/A312M, ASTM A213/213A, ASTM A269/269M | |

| Europe | DIN2462, EN10088, EN110095, EN10259, EN10028 | |

| Japanese | JIS G3463, G3119, G4304, G4309, G4321 | |

| Russia | GOST 11268, GOST 19281 - 89, GOST 19903 - 74, GOST 19904 - 90 | |

| Added Processing | Decoiling, Bending, Perforating, Punching, Cutting, Polishing, Welding | |

| Technique | Cold rolled; Hot rolled; Hot forming; Cold forming; Heat treatment; Machinability; Welding; | |

| Thickness | Cold rolled: 0.3-4 mm or according to customer requirements | |

| Hot rolled: 3-120 mm or according to customer requirements | ||

| Width | 600mm, 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm Customization according to customers’ requirements | |

| Length | 2000mm, 2438mm, 3000mm, 5800mm, 6000mm Customization according to customers’ requirements | |

| Edge | Slit/Mill Edge | |

| Film coating | Species | PVC film/PE film/Laser film/Oil film/Water membrane/Self-lining/Electrostatic film, etc |

| Thickness | 3c/5c/7c/10c and so on | |

| Color | Black/white/Blue or customized | |

| Physical property | Strength of extension: σb ( MPa )≥520 Yield strength σ0.2 (MPa) ≥205 Elongation: σ5(%)≥40 Percentage reduction of area: Ψ(%)≥60 | |

| Application | * 1) Equipment that resists sulfuric acid, phosphoric acid, acetic acid, and acetic acid; * 2) Petrochemical; * 3) Mechanical and electrical hardware; * 4) Shipyard; * 5) Power plant; * 6) Food Processing and Dairy Industries. | |

| Packing | Waterproof paper/Iron/ Wooden pallet or according to customer's requirements | |

| Grade | C | Si | Mn | P | S | Ni | Cr | Mo |

| 304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - |

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| 316L | ≤0 .03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 - 15.0 | 16 .0 -1 8.0 | 2.0 -3.0 |

| 321 | ≤ 0 .08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0 - 13 .0 | 17.0 -1 9.0 | - |

| 904L | ≤ 2 .0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0·28.0 | 19.0-23.0 | 4.0-5.0 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 |

| 430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0.03 | ≤0.60 | 16.0 -18.0 | - |

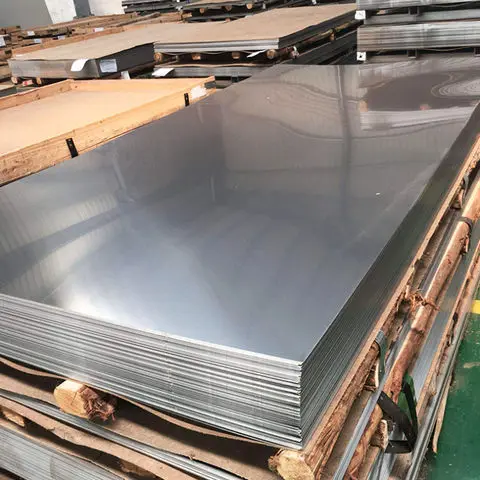

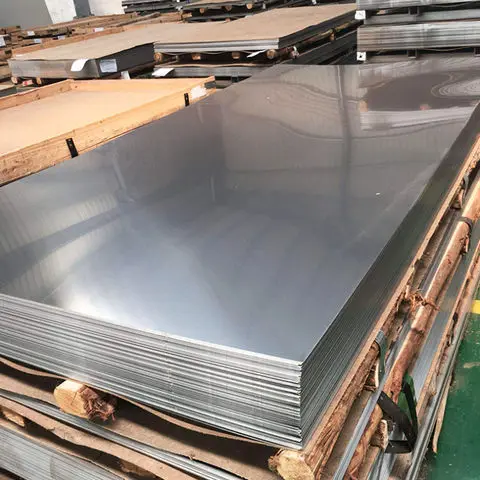

Product Image

| HR VS CR | ||

| HR | CR | |

| Processing | The whole process is done at high temperature and at the end is being cooled down | Cold rolled steel is heated and cooled at the room temperature and then rolled after again |

| Advantage | – Easier to make: heat it up, push through, cool down and that’s it! – Cheaper than cold rolled – Hot rolled steel is allowed to cool at room temperature and it’s free from internal stresses that can arise from quenching or work-hardening processes – Most popular shapes are hot-rolled (UC, UB, SHS, RHS, PFC, flats etc.) | – accurate shape (consistent and straight) – a wider range of surface finishes – a smooth and shinier surface – bars are true and square and have well-defined edges and corners – Tubes have better concentric uniformity and straightness. |

| Disadvantage | – dimensional imperfections caused by heating (expanding) and cooling down (shrink, warpage) – rough texture on a surface, need to be removed and buffed before painting – Slight distortions | – more expensive – fewer shapes available cold-rolled (sheets, box section shapes: CHS, SHS, RHS) – additional treatments can create internal stress within the material; this can cause unpredictable warping if the steel is not stress relieved prior to cutting, grinding, or welding. |

Appication

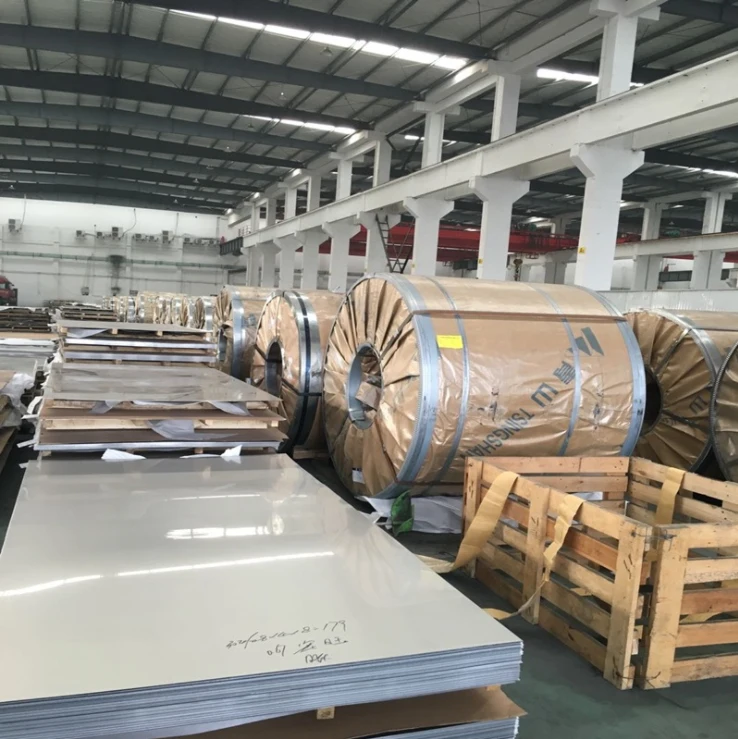

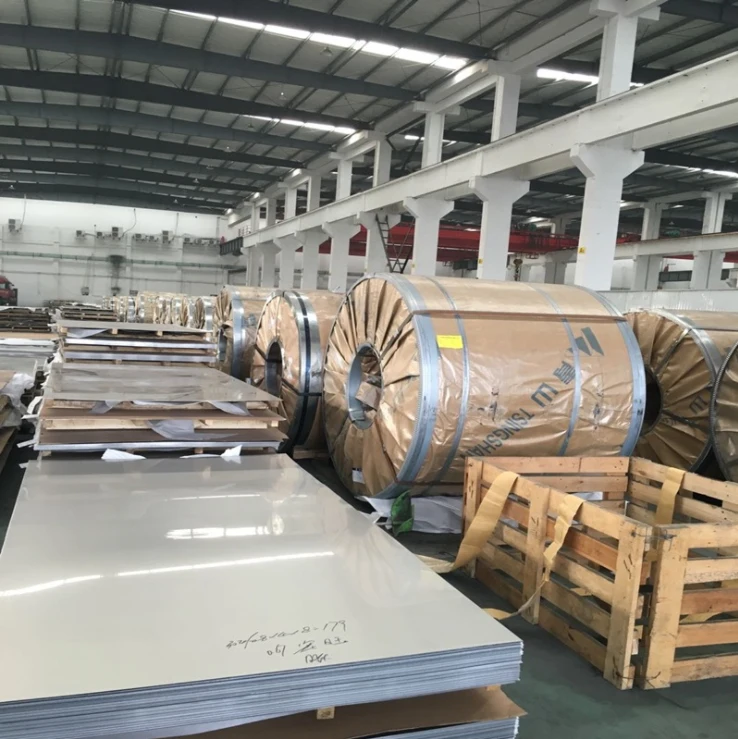

Warehouse

Packing & Delivery

Specification

| Grade | 304 stainless steel sheet plate | |

| Surface | 2B, NO.1, BA, NO.4, 8K, HL, Polished, Mill, Embossing, Satin, ect with PVC/PE/Laser film | |

| Executive Standard | Chinese | GB/T14975-2002, GB/T14976-2002, GB/T13296-91 |

| American | ASTM A312/A312M, ASTM A213/213A, ASTM A269/269M | |

| Europe | DIN2462, EN10088, EN110095, EN10259, EN10028 | |

| Japanese | JIS G3463, G3119, G4304, G4309, G4321 | |

| Russia | GOST 11268, GOST 19281 - 89, GOST 19903 - 74, GOST 19904 - 90 | |

| Added Processing | Decoiling, Bending, Perforating, Punching, Cutting, Polishing, Welding | |

| Technique | Cold rolled; Hot rolled; Hot forming; Cold forming; Heat treatment; Machinability; Welding; | |

| Thickness | Cold rolled: 0.3-4 mm or according to customer requirements | |

| Hot rolled: 3-120 mm or according to customer requirements | ||

| Width | 600mm, 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm Customization according to customers’ requirements | |

| Length | 2000mm, 2438mm, 3000mm, 5800mm, 6000mm Customization according to customers’ requirements | |

| Edge | Slit/Mill Edge | |

| Film coating | Species | PVC film/PE film/Laser film/Oil film/Water membrane/Self-lining/Electrostatic film, etc |

| Thickness | 3c/5c/7c/10c and so on | |

| Color | Black/white/Blue or customized | |

| Physical property | Strength of extension: σb ( MPa )≥520 Yield strength σ0.2 (MPa) ≥205 Elongation: σ5(%)≥40 Percentage reduction of area: Ψ(%)≥60 | |

| Application | * 1) Equipment that resists sulfuric acid, phosphoric acid, acetic acid, and acetic acid; * 2) Petrochemical; * 3) Mechanical and electrical hardware; * 4) Shipyard; * 5) Power plant; * 6) Food Processing and Dairy Industries. | |

| Packing | Waterproof paper/Iron/ Wooden pallet or according to customer's requirements | |

| Grade | C | Si | Mn | P | S | Ni | Cr | Mo |

| 304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - |

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| 316L | ≤0 .03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 - 15.0 | 16 .0 -1 8.0 | 2.0 -3.0 |

| 321 | ≤ 0 .08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0 - 13 .0 | 17.0 -1 9.0 | - |

| 904L | ≤ 2 .0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0·28.0 | 19.0-23.0 | 4.0-5.0 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 |

| 430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0.03 | ≤0.60 | 16.0 -18.0 | - |

Product Image

| HR VS CR | ||

| HR | CR | |

| Processing | The whole process is done at high temperature and at the end is being cooled down | Cold rolled steel is heated and cooled at the room temperature and then rolled after again |

| Advantage | – Easier to make: heat it up, push through, cool down and that’s it! – Cheaper than cold rolled – Hot rolled steel is allowed to cool at room temperature and it’s free from internal stresses that can arise from quenching or work-hardening processes – Most popular shapes are hot-rolled (UC, UB, SHS, RHS, PFC, flats etc.) | – accurate shape (consistent and straight) – a wider range of surface finishes – a smooth and shinier surface – bars are true and square and have well-defined edges and corners – Tubes have better concentric uniformity and straightness. |

| Disadvantage | – dimensional imperfections caused by heating (expanding) and cooling down (shrink, warpage) – rough texture on a surface, need to be removed and buffed before painting – Slight distortions | – more expensive – fewer shapes available cold-rolled (sheets, box section shapes: CHS, SHS, RHS) – additional treatments can create internal stress within the material; this can cause unpredictable warping if the steel is not stress relieved prior to cutting, grinding, or welding. |

Appication

Warehouse

Packing & Delivery